Example

Elongation of wires where stress varies along length of wire

Example: A solid sphere hung at the lower end of a wire is suspended from a fixed point so as to give an elongation of mm. When the first solid sphere is replaced by another one made of same material but twice the radius, what is the new elongation?

Solution:as radius is doubled volume becomes 8 times and, hence, the weight of sphere. The force becomes 8 times

also becomes 8 times

Solution:as radius is doubled volume becomes 8 times and, hence, the weight of sphere. The force becomes 8 times

also becomes 8 times

Law

Hooke's law and assumptions

According to Hooke's law strain produced in any body, is directly proportional to stress applied within the elastic limit. Moreover, For a spring, needed to extend or compress by some distance is proportional to that distance. That is, , where is a constant factor characteristic of the spring: its stiffness, and is small compared to the total possible deformation of the spring.

Assumption:

1. This law is true only for linear elastic bodies.

Definition

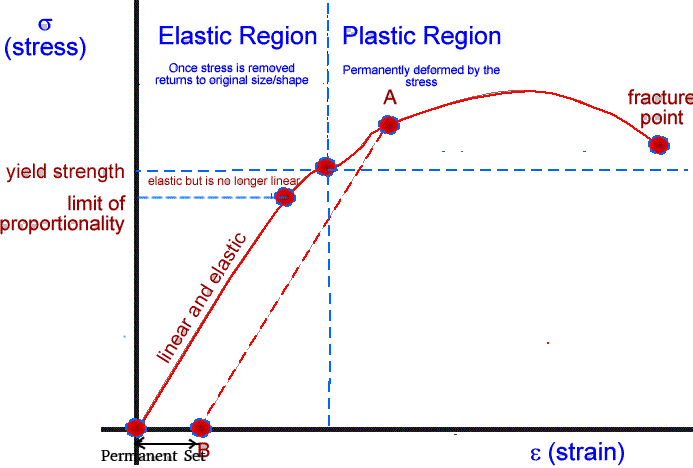

Elastic range and proportional limit on a stress-strain curve

Elastic Range: The limit of strain produced on the material up to which original shape of the material can be restored is considered as elastic range. On application of force in elastic range material restores its shape once the force is removed.

Proportional Limit: Its a point on the stress-strain curve up to which stress in proportional to strain.

Proportional Limit: Its a point on the stress-strain curve up to which stress in proportional to strain.

Definition

Yield Point and Yield Strength

Stress strain curve yield point is the material property defined as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible.

The yield point determines the limits of performance for mechanical components, since it represents the upper limit to forces that can be applied without permanent deformation.

The mechanical strength of the material corresponding to yield point is defined as yield strength.

The yield point determines the limits of performance for mechanical components, since it represents the upper limit to forces that can be applied without permanent deformation.

The mechanical strength of the material corresponding to yield point is defined as yield strength.

Definition

Permanent set and plastic deformation in a material

When the load on a wire is increased beyond the yield point, the stress developed exceeds the yield strength. If the load is removed after this point, the body does not regain its origin volume but gets a little deformed. Here, strain is non-zero even if the stress is zero. This property of the material is known as the permanent set and the deformation is called plastic deformation.

Definition

Plastic range on a stress-strain curve

When the stress is sufficient to permanently deform the metal, it is called plastic deformation. The plastic region is the portion where some permanent deformation will occur, even if the load is removed.

Failure point is when the specimen fractures.

Failure point is when the specimen fractures.

Definition

Ductile and brittle solids

Ductile materials, which includes structural steel and many alloys of other metals, are characterized by their ability to yield at normal temperatures.

Brittle materials, which includes cast iron, glass, and stone, are characterized by the fact that rupture occurs without any noticeable prior change in the rate of elongation.

Brittle materials, which includes cast iron, glass, and stone, are characterized by the fact that rupture occurs without any noticeable prior change in the rate of elongation.

Diagram

Stress-Strain Curve

Definition

Elastic Hysteresis

Stress-strain curve for rubber is shown in the attached figure. It is different from the usual stress-strain curve in two ways:

1. In no part of the curve, strain changes linearly with change in applied stress.

2. During unloading, the curve does not retrace its path.

Work done by the material in returning to its original shape is less than the work done by the deforming force when it is deformed. A particular amount of energy is absorbed by the material. This phenomenon is called elastic hysteresis.

1. In no part of the curve, strain changes linearly with change in applied stress.

2. During unloading, the curve does not retrace its path.

Work done by the material in returning to its original shape is less than the work done by the deforming force when it is deformed. A particular amount of energy is absorbed by the material. This phenomenon is called elastic hysteresis.

Definition

Yield Strength

Yield strength refers to an indication of maximum stress that can be developed in a material without causing plastic deformation.

It is the stress at which a material exhibits a specified permanent deformation and is a practical approximation of the elastic limit

It is the stress at which a material exhibits a specified permanent deformation and is a practical approximation of the elastic limit

| BookMarks |

0 Comments

Post a Comment